Image credit: frozen Brazilian fruit dessert

What is flash freezing?

Image created by Canva

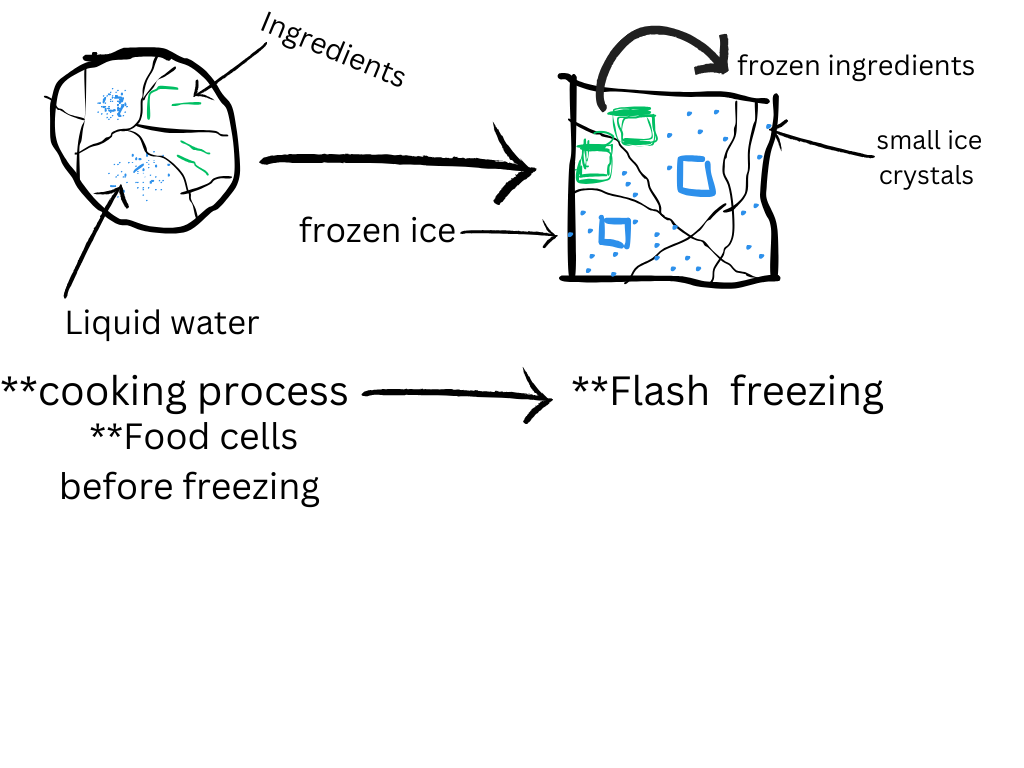

The simple definition of flash freezing is lowering temperature—32F or 0C—of food ingredients and keeping the cells in the food or any item intact. The diagram above shows a simple illustration of what happens when food undergoes flash freezing. The ingredients in the food item remain intact while the surrounding solution freezes. Furthermore, this process reduces shipping costs and spoilage because water is frozen in the food item. Another benefit is retention in nutrition content of the final product, such as vitamins and minerals. To note here, ice crystals affect cell integrity over a period of time. As my diagram shows, the cellular structure—before freezing and after flash freezing—has a significant difference. The left diagram illustrates a cell structure that is intact before freezing, while the frozen food item has smaller ice crystals.

Image credit: Unsplash by Maryam

Does flash freezing work for plant-based milk?

Temperature control is a big factor in keeping shelf life longer for plant-based milk. Based on Journal of Food Engineering, the textural attributes and temperature are directly related, which can lead to a different viscosity for the final product. Plant-based milk requires colder temperatures to remain shelf-stable. This brings us to the flash freeze option. As you can see from my diagram—fewer ice crystals are formed in the final product. This change in cell structure improves product quality and safety. The reason for this is less damage during defrosting as the ice crystals are not large. Moreover, flash freezing equipment increases moisture retention in thawed and cooked products like baked goods and produce. There is reduced damage to the cells, in turn, a better plant-based milk product is manufactured for the customer. An example of a company that applies this manufacturing process is called Good Mylk. On the other hand, you can utilize a blast freezer to improve shelf life for a variety of products. For example, the Journal of Food Science and Technology, mentions a six month shelf life of date juice packed in low density polyethylene bags.

Image credit: assortment of frozen food on the table

Options for reducing oxygen and spoilage with flash freezing:

Food spoilage is a result of several factors—one of which is the level of moisture in the food. Using flash freezing is a great way to reduce this, and could be a great option in the case of plant-based milks. Several options can be applied to improve the quality and safety of the product. First, after flash freezing; keep the container away from light, use a stainless-steel container, and dark containers. As a result, this helps keep the light out and reduces oxidation. Possible options: A tinted glass container might be a possibility for plant-based milk. Second, based on the Journal of Food Science and Technology, nitrogen flushing pumps out oxygen, which protects the flavor and vitamin content of milk. Furthermore, airtight containers can help seal the bottle tight against oxygen. Possible option: polyethylene terephthalate/low-density polyethylene pouches. Third, plastic pouches are bad for the environment, and contamination of milk can occur. BPA free option maybe are available? Even with that, is it safe? Possible option: using a heat seal and an eco-friendly package, and assessing your personal needs by using the form by the Netherlands Institute for Sustainable Packaging. Lastly, Chemical and Engineering News mentions prolong shelf life and oxidation of plant-based milk with rosemary, organic acids through fermentation, mustard oil, and other antimicrobial products. A combination of different natural preservatives is required to provide the maximum benefit.

To note here, one issue with flash freezing is the degradation of nutritional quality in nuts and seeds. This can lead to a risk of microbiological contamination due to the water content. Therefore, there is a need for oxygen absorbers to increase the shelf life of plant-based milks.

As you can see, alteration in water content of a product can change microbiological activity. Therefore, flash freezing can help control the water content, and in turn, improve the quality and food safety of the final product.

References

- Blair, B. (2023). 9 Differences Between Freezing and Freeze Drying Food. EZ-Prepping. Website: 9 Differences Between Freezing and Freeze Drying Food (ezprepping.com)

- Bomgardner, M. (February 10, 2014). American Chemical Society, 92 (6). Extending Shelf Life With Natural Preservatives. Website: https://cen.acs.org/articles/92/i6/Extending-Shelf-Life-Natural-Preservatives.html

- Maghsoudlou,Y. et al. (20 November 2015). Journal of Food Processing and Preservation, 40 (5), pp 828-839. Optimization of Ultrasound-Assisted Stabilization and Formulation of Almond Milk. Website: https://ifst.onlinelibrary.wiley.com/doi/pdf/10.1111/jfpp.12661

- Rysstad, G. (21 April 2006). International Journal of Dairy Technology, 59 (2), pp 85-96. Extended shelf life milk—advances in technology. Website: https://onlinelibrary.wiley.com/doi/full/10.1111/j.1471-0307.2006.00247.x

- Tazi, S. et al. (14 January 2009). Food Chemistry, 115 (3), pp 958-964. Effects of light, temperature and water activity on the kinetics of lipoxidation in almond-based products. Website: https://www.sciencedirect.com/science/article/pii/S0308814609000405

- Simuang, J. et al. (7 November 2003). Journal of Food Engineering, 64 (2), pp 193-197. Effects of fat content and temperature on the apparent viscosity of coconut milk. Website: https://www.sciencedirect.com/science/article/abs/pii/S0260877403003923

- Kulkarni, S.G. et al. (2010). J Food Sci Technol, 47, pp 157–161. Effect of processing of dates into date juice concentrate and appraisal of its quality characteristics. Website: https://link.springer.com/article/10.1007/s13197-010-0028-y

- Cichello, SA (2015). J Food Sci Technol, 52(4), pp1889-95. Oxygen absorbers in food preservation: a review. J Food Sci Technol. Website: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4375217/#!po=20.5357

- D. S. Johnson et al. (February 04, 2015). American Dairy Science Association, 98 (4), pp 2205-2214. Packaging modifications for protecting flavor of extended-shelf-life milk from light. Website: http://dx.doi.org/10.3168/jds.2014-8857

- Flash Freeze. Website: http://flash-freeze.net/freezer-types/3dfreezer.html

- Good Mylk. Website: https://goodmylk.co/

- Freeze-Drying Food (Oct 22, 2019). Lyophilization World. Website: https://www.lyophilizationworld.com/post/2019/10/22/freeze-drying-food

- Suitability assessment food packaging materials. Netherlands Institute for Sustainable Packaging. Website: 20220309_08_beslisboom_voedselverpakkingsmateriaal_eng_def.pdf (kidv.nl)

Pingback: Food science topics – Alimentative