Vacuum Steam pulsed blanching (VSPB)

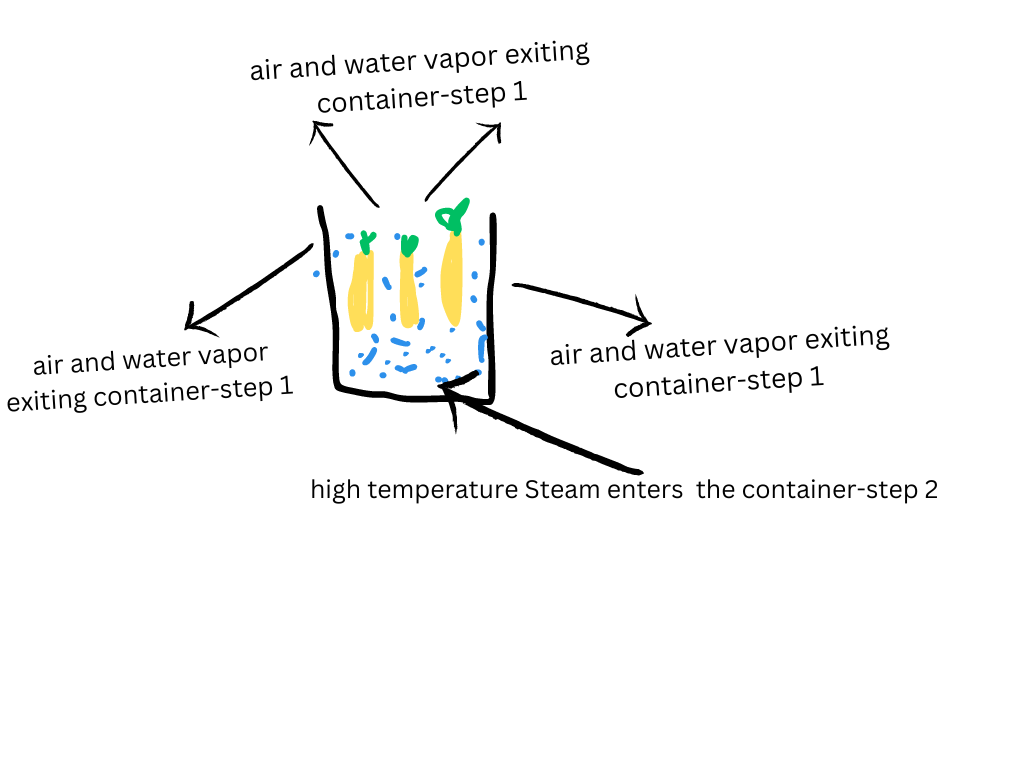

Hui et al., provides research on this type of technology. During the process of packaging, there is a need to blanch the vegetable. This changes the texture, and speeds up the drying rate of different fruits and vegetables. Also, there is a change in water content and cell structure. Therefore, VSPB alters the final product. To note here, the process is a type of blanching that doesn’t require water, and reduces food waste, in the process. Though this new technology still needs more studies to find out how effective it is. Questions I think that need to be answered, how does removing water improve food safety? and how does water play an important role in this technology? more on this later on. The diagram below explains about the process of VSPB. After step two, the vegetable or fruit is exposed to the steam for a longer period, and in turn, a gradual decrease in temperature occurs. This helps stop the blanching; the whole process repeats as many times as necessary by the manufacturer:

Created by canva

Continue reading