Vacuum Steam pulsed blanching (VSPB)

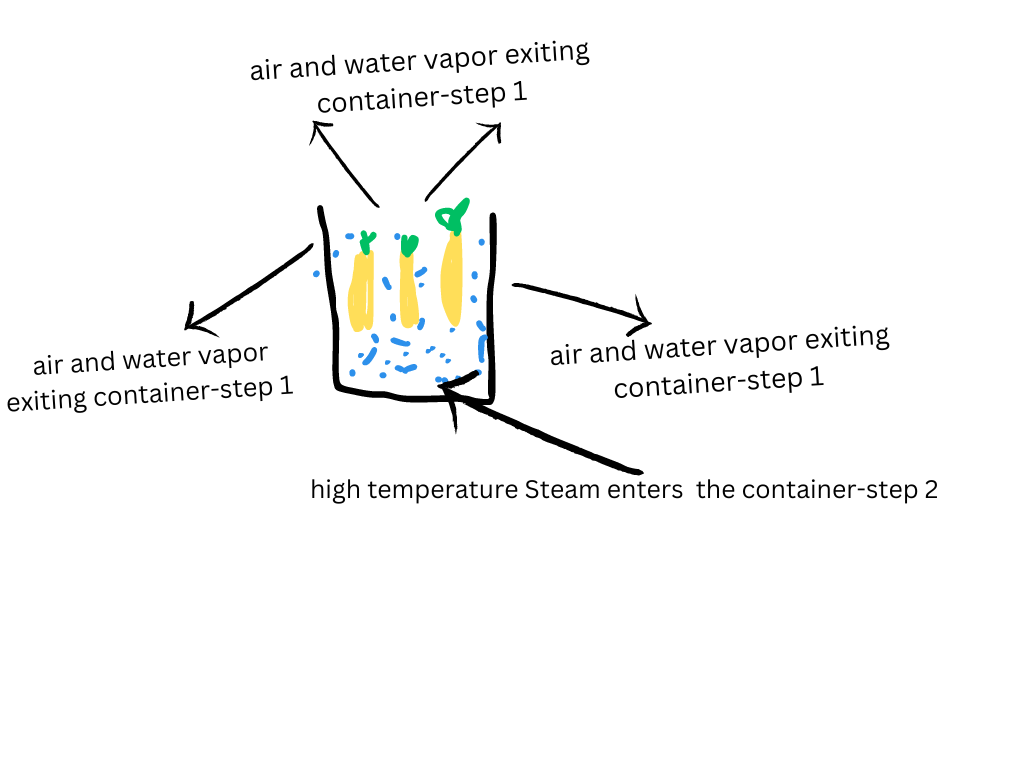

Hui et al., provides research on this type of technology. During the process of packaging, there is a need to blanch the vegetable. This changes the texture, and speeds up the drying rate of different fruits and vegetables. Also, there is a change in water content and cell structure. Therefore, VSPB alters the final product. To note here, the process is a type of blanching that doesn’t require water, and reduces food waste, in the process. Though this new technology still needs more studies to find out how effective it is. Questions I think that need to be answered, how does removing water improve food safety? and how does water play an important role in this technology? more on this later on. The diagram below explains about the process of VSPB. After step two, the vegetable or fruit is exposed to the steam for a longer period, and in turn, a gradual decrease in temperature occurs. This helps stop the blanching; the whole process repeats as many times as necessary by the manufacturer:

Created by canva

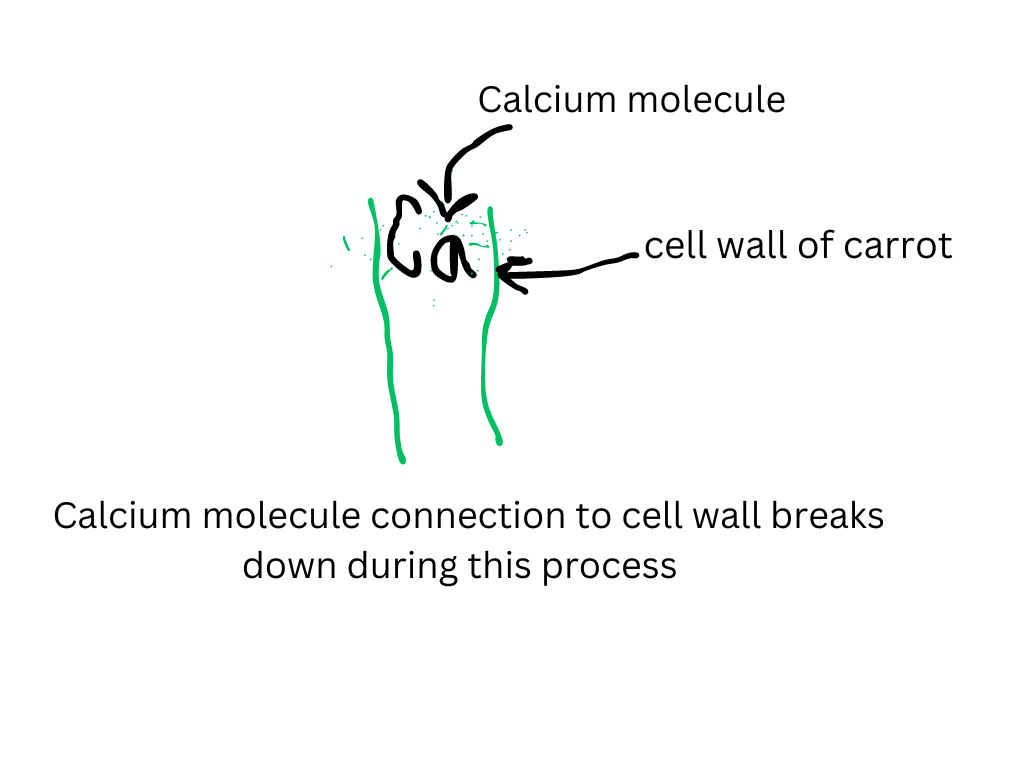

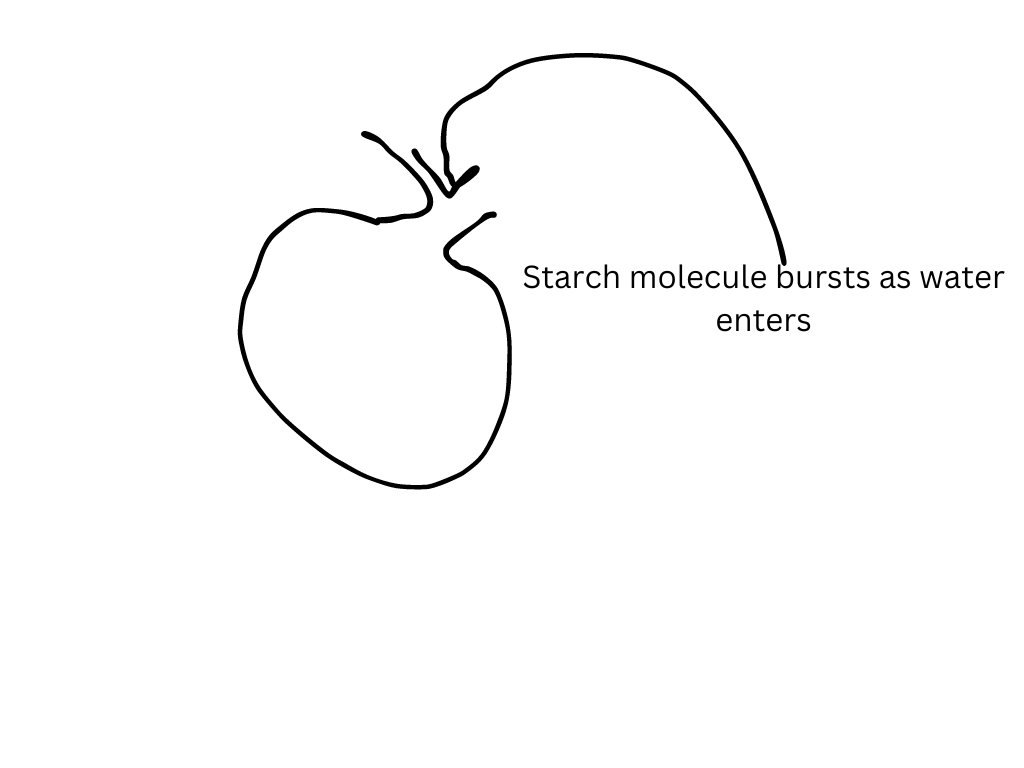

The blanching process damages the structure of the product, and forms lipid droplets containing calcium ions. This leads to water lose, as the cell wall starts degrading. Think of this as a starch molecule losing its structure. As more water enters, it loses turgidity. Similar concept here, but the cell wall is breaking down.

Versus starch molecule:

Created by canva

Dehydration process and food safety

The technology and water, both play an important part in food safety. This answer the questions I posed in the beginning of the article. Water is a major component of most foods, influences texture, taste, appearance, and spoilage of food products. This brings us to the topic of food stability – also called shelf life – which is the life expectancy of a food or product that we consume every day. For example, there is more free water in fruit like an apple than a jam. This is due to sugar binding to the water in the jelly versus free water in the fruit. Despite the difference, both have high water content. Another good binder to water is pectin and glycerol. Keep in mind, salt is six times better binder to water than sugar. Also, the more free water available, the more microbial growth occurs in the product or food. As I explained; water affects the texture of food. For example, a cookie that has added sugar traps moisture which gives it a chewy texture. As you can imagine, cookies have different textures based on how much sugar or liquid is added. This is why texture and moisture change so much with each new recipe you try online or in your favorite cookbook.

This brings us to the technology and its relation to water. The less water is in the vegetable, in this case, carrots. The less microbial activity, and safer the product is. Also, the dehydration process is faster. So, it seems like this type of technology has a potential to provide a safe, efficient product for the customer.

References

- Industrial applications of selected JFS articles (2024). J. Food Sci., 89: pp. 4-7. Website: https://doi.org/10.1111/1750-3841.16924

- Wang, Hui et al. (2021). Vacuum-steam pulsed blanching (VSPB) softens texture and enhances drying rate of carrot by altering cellular structure, pectin polysaccharides and water state. Innovative Food Science and Emerging Technologies, 74, Article number: 102801. Website: https://www.sciencedirect.com/science/article/abs/pii/S1466856421002022?via%3Dihub

- Pei, Yu-Peng et al. (2022). Effect of vacuum-steam pulsed blanching (VSPB) on drying characteristics and quality properties of garlic slices. Drying Technology, 40 (6): pp. 1232-1246. Website: https://www.ingentaconnect.com/content/tandf/ldrt/2022/00000040/00000006/art00014.

- Zhang AA, Ha BE, Chen C, et al. (2024). Vacuum-steam pulsed blanching: An emerging method to enhance texture softening, drying behavior and physicochemical properties of Cornus officinalis. J. Food Sci., 89 (1): pp. 202-216. Website: https://europepmc.org/article/MED/38078765

Pingback: Food science topics – Alimentative