What is HPP?

HPP has many benefits, as the logo shows by Hiperbaric. The logo was developed in 2017 to provide a standardized certificate for food safety. Customers can trust the company since the logo indicates high food safety standards, transparency of ingredients, and increasing nutrient-dense products. To also add, clean label foods, is transparency of ingredients, void of artificial ingredients, and lack of common allergens. This is a challenge that most food manufacturers face, as more and more consumers are demanding healthier ingredients. The HPP process has provided products that are clean label foods which answer consumers’ needs. For example, companies such as MUSH, Once Upon a Farm, and Evolution Fresh have been revolutionizing food processes by utilizing the HPP process. This process keeps the nutrients by using less heat, utilizes fewer preservatives, and increases food safety and shelf life.

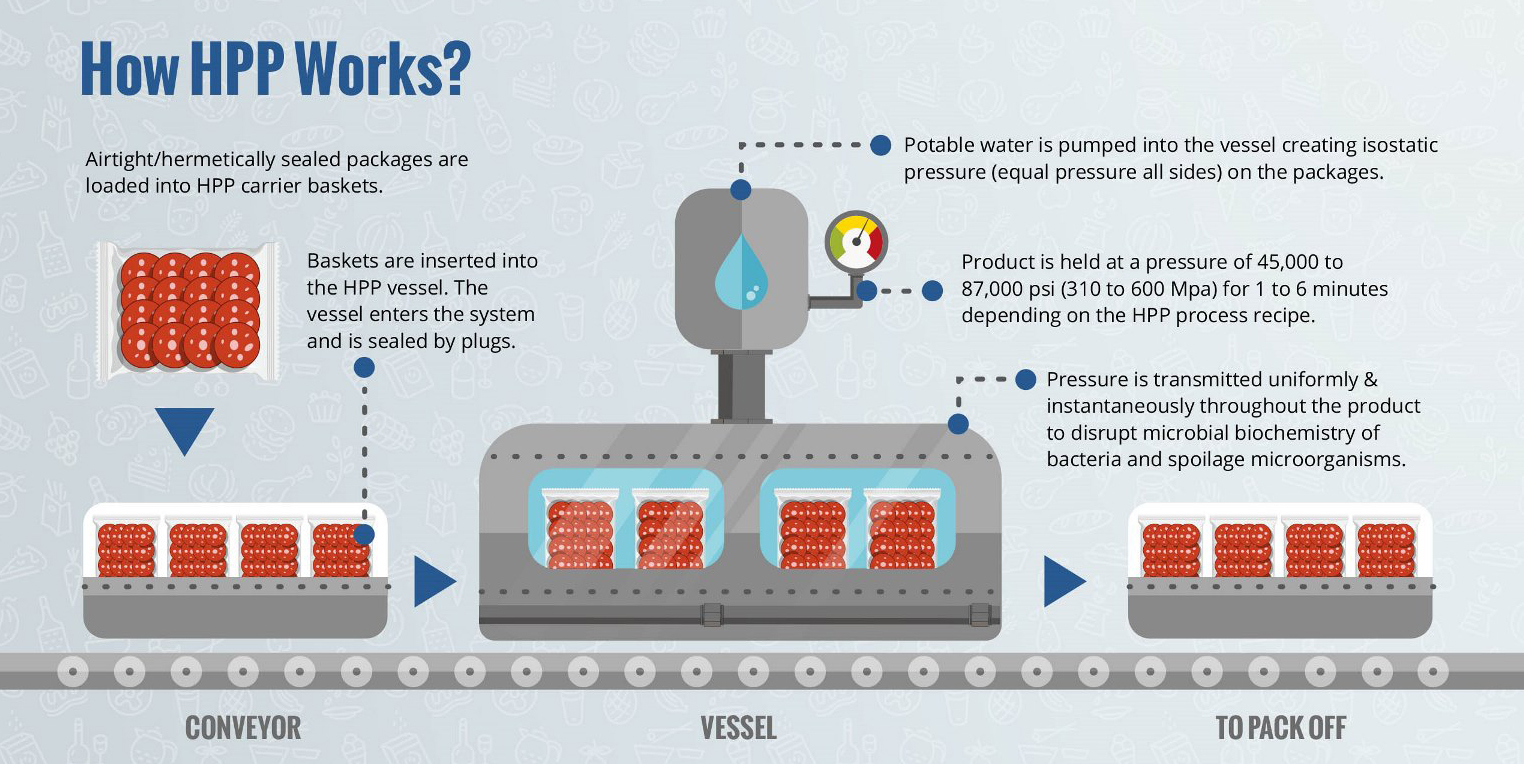

Steps of HPP technology

Image credit: food safety tech

The diagram above shows a basic overview of the HPP process. Food Business News mentions, “The H.P.P. system involves the loading of airtight/hermetically sealed packages into carrier baskets. The baskets are inserted into the H.P.P. vessel, which then gets sealed by plugs. At this point, potable water is pumped into the vessel creating isostatic pressure (equal pressure on all sides) on the packages. Product is held at a high pressure for up to six minutes, with pressures and times varying by product. The pressure disrupts the microbial biochemistry of pathogens and spoilage bacteria, which helps preserve freshness and increase shelf life.”

HPP applications

Food Business News continues by saying, “The pressure processing technology transitioned from the lab to the production floor almost 20 years ago. Now, it is gaining greater recognition among consumer-packaged goods companies for a variety of products. The leading benefits of H.P.P. include destruction of pathogens, pasteurizing product within its packaging, extending shelf life, developing cleaner label products and reducing food waste.” One example is removing salt in deli meat. As shown in the diagram by meat +poultry, Hormet deli meat is one company that is taking advantage of this new technology. Moreover, meat + poultry, continues to explain the breakdown of each food sector.

Keep in mind though that the process for HPP has a different food safety step than say centrifuge technology. As Food Business News continues, “Cold-pressed juice manufacturers typically employ H.P.P. to ensure food safety. Ms. Longfield said that cold-pressed juice manufacturers must be careful when explaining the cold-pressed process. This is a process that relies on a slow pulverizer with hydraulic press to extract juice, as compared to more traditional centrifugal juicing processes. It does not include a food safety or preservation step. In order to obtain about a 30-day refrigerated shelf life, cold-pressed juices typically undergo the additional step of H.P.P. to kill potentially harmful microorganisms. Juice and beverage producers are the fastest-growing sector for H.P.P., Ms. Longfield said. They accounted for 50% of H.P.P. equipment installations in the past three years.”

HPP technology is on the rise as more and more customers are requiring companies to be sustainable, nutrient dense, food safe, and healthy. HPP logo certification is not a requirement with food manufacturing since it is a new technology. However, customers need explanation, education, and transparency of ingredients and the logo will provide this.

On a lighter note, Ellen talks with the founder of once upon a farm, one of the companies that use HPP. Great addition to my HPP blog this week 🙂

Check it out: https://www.youtube.com/watch?v=x-sztMnAico

References

2. Website: https://www.newhope.com/news/new-certification-brings-awareness-transparency-hpp-technology

3. Website: https://www.foodbusinessnews.net/articles/11667-using-pressure-to-fuel-premium-beverage-innovation

4. Website: https://www.foodbusinessnews.net/articles/9173-high-pressure-processing-providers-and-users-partnering-to-promote-technology – sign up for free to see the article.

5. Website: https://onceuponafarmorganics.com/blog/how-hpp-is-changing-the-baby-food-aisle/

6. Website: https://www.meatpoultry.com/articles/16158-hpp-processors-form-cold-pressure-council

7. Website: https://www.hiperbaric.com/en/global-trends-in-hpp-for-2019/

Sorry- I don’t know how I missed these! Glad you are blogging again.

I gotta catch up. Katie

On Mon, Feb 11, 2019, 10:28 PM Living Well In The 21st Century wrote:

> Muayyad Karadsheh posted: ” What is HPP? The figure above provides the > main benefits of HPP. The logo was developed in 2017 to provide a > standardized certificate for food safety. Customers can trust the company > since the logo indicates high food safety standards, transparency of ” >

LikeLike

No worries 🙂 thanks for reading. Anything you can add about HPP?

LikeLike

Pingback: Food manufacturing – Alimentative

Pingback: Food science topics – Alimentative